Continual investment is at the forefront of our operations at Eminox, and our most recent programme has brought greater operational, and health and wellbeing benefits to our UK HQ.

The investment, of more than £1M, has seen significant operational improvements to our manufacturing areas to allow the installation of key equipment which elevates our production facilities and brings tangible benefits to all our stakeholders.

Investment in machinery

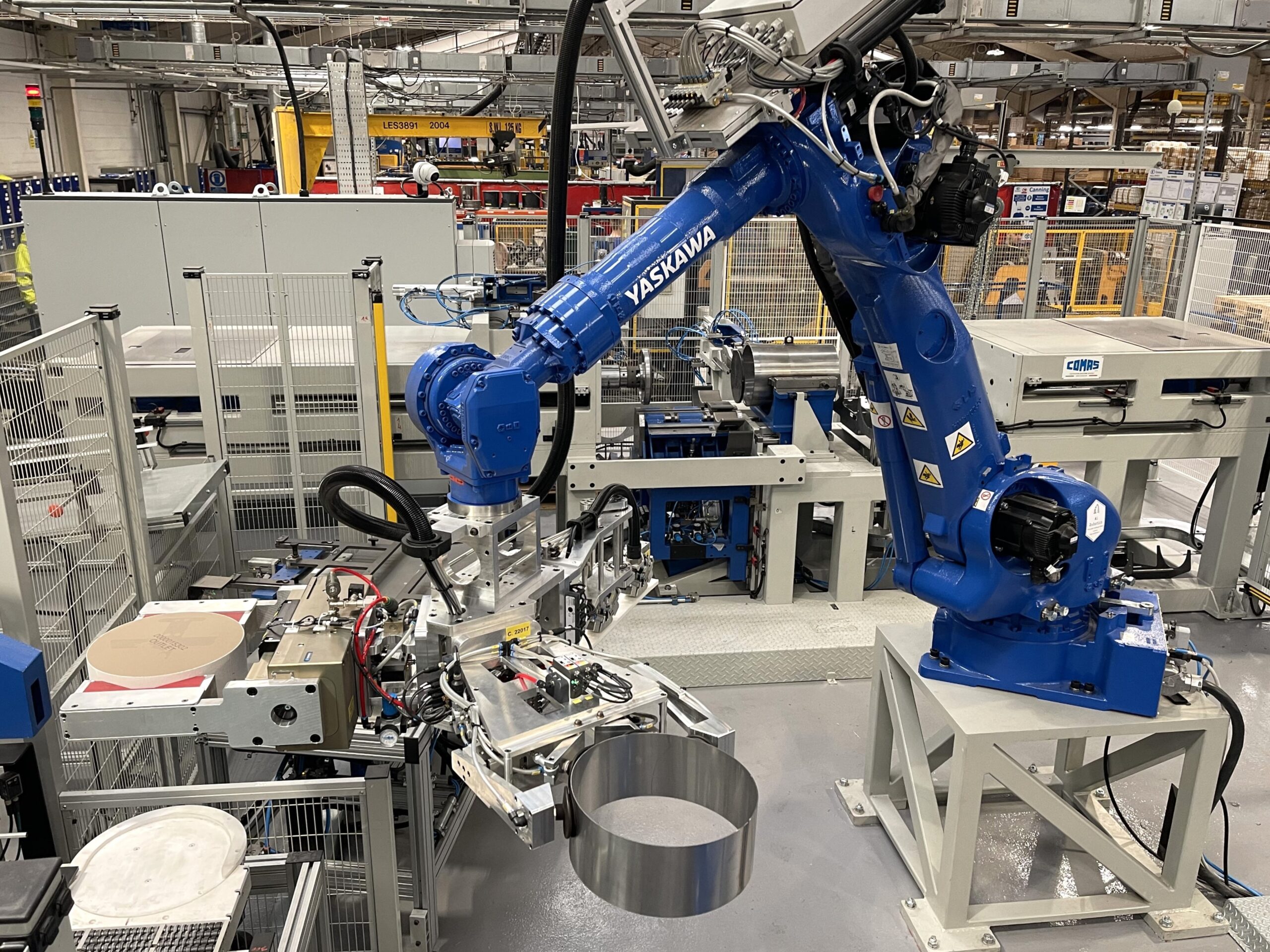

The focal point of the installation is a Comas automated canning line which provides flexibility and consistent quality in volumes to suit customer demand for our exhaust aftertreatment systems (EATS). This helps us to support customers, at our accredited facility, across many industry sectors who require the latest in emission reduction technologies including maritime, on road, power generation, agriculture, non-road mobile machinery (NRMM) and rail.

This is complemented by a Comas servo press with a capacity of 80 tonne, delivering enhanced features including precision control over both speed and position and the large bed area can accommodate larger tools meaning greater flexibility for customers.

The press is driven by twin servo motors rather than being hydraulically powered. This gives greater flexibility in meeting operational and production targets for pre-forming and final forming strokes and unique programming for each tool to ensure quality and precision in manufactured components.

Finally, our large-scale exhaust aftertreatment (EATS) welding platform has brought an enhanced level of accuracy to our production capabilities, allowing us to support some of the largest engine manufacturers in the world with precision engineering, particularly in the maritime and power generation sectors.

This investment enables our manufacturing team to:

- Have great flexibility as tooling is interchangeable between this and our other welding platforms.

- Configure the platform to accommodate the different sized units being built.

- Reduce weld distortion by efficiently clamping material to the flat surface and enabling faster changeovers due to a quick release clamping system.

- Add to its capabilities with future smaller investments depending on customers’ requirements.

Investing in our people

The installation of Indeva lifting equipment has reduced the amount of manual lifting and manoeuvring of our products carried out by our workforce through assisted lifting for a seamless operation.

Additionally, the installation of Kardex units to streamline our inventory management and create more manufacturing space also reduces potential risks for our team, bringing HSE benefits.

What our team say

“These investments support our vision for the business and also our Environmental, Social and Governance values that are helping to determine the future of the business,” said Greg Kent, Operations Director, Eminox. “By improving efficiencies, reducing risk, and considering the impact we make in all aspects of our business operations, we will maintain our reputation as a pioneer of emissions reduction technologies and as a responsible supplier, customer and employer.”

Eminox welcomes visits from customers and the team would be delighted to show you the new equipment in operation.

Simply talk to a sales team member to arrange a meeting.