Power Generation EMISSIONS REDUCTION TECHNOLOGIES

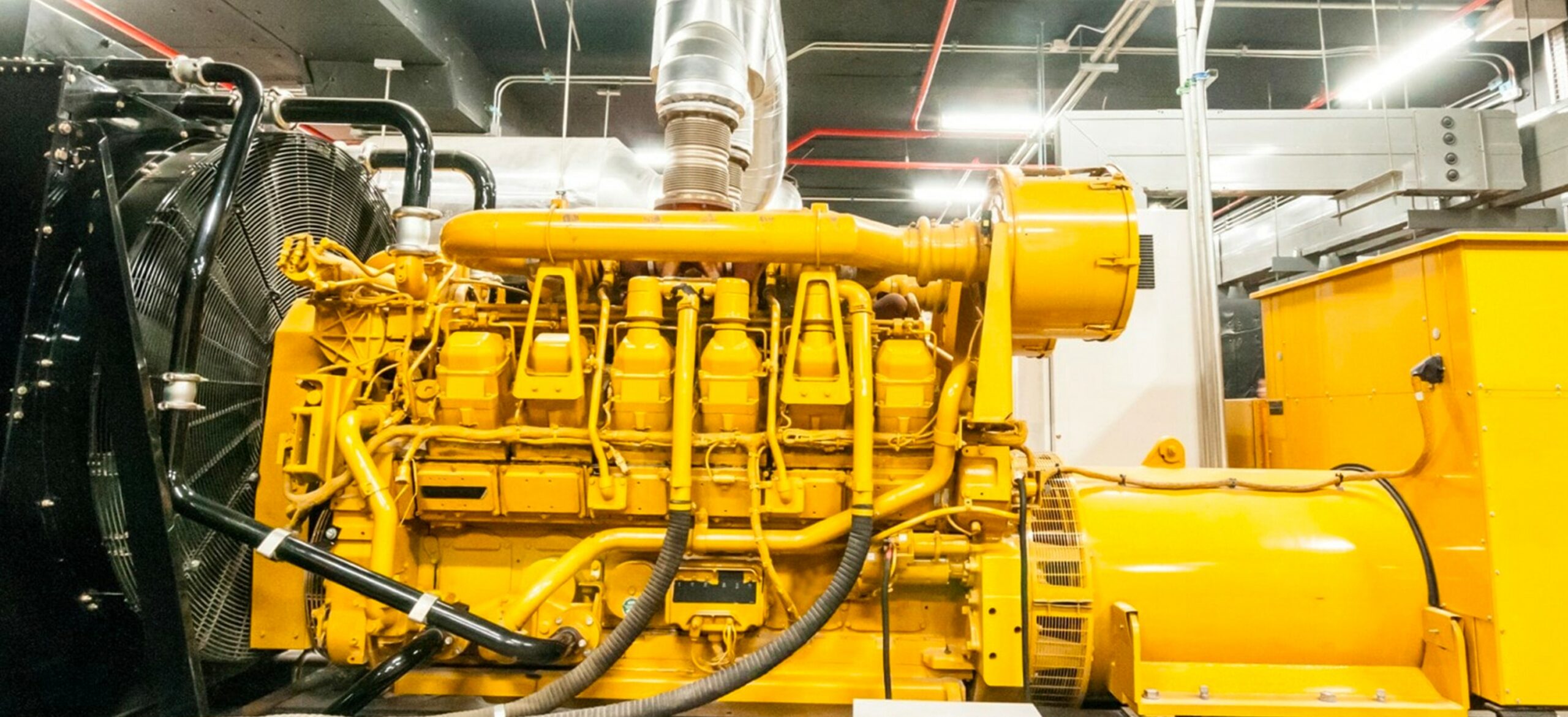

Eminox is a pioneer of power generation emissions reduction technology, exhaust aftertreatment systems for heavy duty engines. We recognise populations are growing and so too are pressures on energy resources increasing the use of independent power generation, globally.

Eminox understands the criteria businesses must meet to comply with the latest power generation emissions legislation and the growing emphasis on ESG frameworks, therefore, we work in partnership with you to develop Original Equipment Manufacturers (OEM) and retrofit emissions solutions for Gensets.

Tier 1 and Tier 2 solutions EMISSIONS SOLUTIONS FOR GENSETS

If you require combined particulate matter (PM) and nitrogen oxides (NOx) reduction our expert engineering capabilities means we can develop, test, manufacture and supply your exhaust aftertreatment system to meet the latest global emissions standards. Therefore, providing a solution to suit your project including those where space is minimal or restricted.

Our proven track record has seen us supply original equipment manufacturers, such as Volvo Penta, for over a decade.

As a Tier 1 and Tier 2 supplier, we are adept at providing power generation emissions solutions for a range of exhaust aftertreatment system challenges and our research and development into new technologies to support alternative fuels means we will continue to support the power generation sector on its journey to net zero.

Power generation upgrade

Eminox has a range of exhaust aftertreatment systems to meet the latest emissions legislation of diesel and gas powered gensets, up to 7MW and holds the required approvals to retrofit gensets from 40kW to 560kW, as accredited by the Energy Savings Trust in the UK.

Our experience and capabilities offer cost effective solutions to upgrade genset equipment to the latest power generation emissions standards including Stage V and the Medium Combustion Plant Directive (MCPD) legislation; whilst extending the service life and providing an alternative to buying a new generator.

Our pioneering DPF technologies and proven SCR technology products support the drive to improve public health and stay ahead of emissions reduction regulations and the growing number of Low Emission Zones, worldwide.

We are proud to be members of AMPS and Europgen trade associations, who are an industry voice for the UK and Europe’s world-leading diesel and gas-engine power generation sector.

FREQUENTLY ASKED QUESTIONS

Here you’ll find the most common questions asked about emissions control and how exhaust aftertreatment systems positively impact on the reduction of emissions in the power generation industry.

Eminox has emission aftertreatment systems which reduce power generation emissions from diesel and gas powered applications and ensure all types and ages of power generators can comply to Medium Plant Combustion Directive (MCPD), Stage V emissions or local regulations.

Our real-world proven emission aftertreatment systems, chosen for their reliable and consistent performance, reduce Particulate Matter (PM) and Nitrogen Oxide (NOx) in support of the power generation industry’s drive to reduce global air pollution by enabling the latest emissions compliance.

The Eminox range of emission control exhaust aftertreatment systems is already developed using a standard range of components, providing a modular and scalable platform product range. This means customers can choose a standard product to suit their individual requirements. However, we also develop solutions specific to your power generation emissions project requirements.

Eminox can provide all service requirements and replacement parts based on the operating hours of each application, with all serviceable components available to maintain the system.

Depending upon the generator set duty cycle service intervals can vary however, at the point of project enquiry, all service plans will be recommended by Eminox.

Yes, they can. Our systems are MCPD, EPA Tier 4 regulations and Stage V compliant covering hire, emergency backup, prime and continuous rated generators meaning solutions for both temporary and permanent installations are available.

Our emission aftertreatment systems for the power generation sector range in size from 60kW to 3000kW.

Whilst our Selective Catalytic Reduction (SCR) technology will successfully enable diesel powered gensets to become NOx compliant, the addition of a Diesel Oxidation Catalyst/Diesel Particulate Filter (DOC/DPF) enables the reduction of up to 99% of harmful particulate matter (PM) to elevate compliance to Stage V standards and showcase the Environment, Social and Governance commitment of generator owners, operators, and manufacturers.

The combination of SCR and DPF technologies is a solution that is proven in real world

operating environments, and which maximises the reduction of emissions, future proofing diesel powered generators in power generation industries.

We have many sizes of emission aftertreatment systems to suit different engine power outputs. As an example, in a recent project completed, the compact aftertreatment system for a 1,400kVA set was mounted on the roof of the generator resulting in no additional floor space being consumed/used/taken. The dimensions of this example are 2550mm (l) x 1830mm (w) x 1740mm (h).

The flexible, scalable, modular design of our exhaust aftertreatment systems allows us to tailor solutions for all genset types and space envelopes to upgrade systems to meet required emissions legislation. Our solutions are developed to be compact, however each system is sized to suit the engine exhaust gas flow and to respect the back pressure and NOx (nitrogen oxides) conversion requirements.

This methodology helps to achieve near zero emissions of PM (particulate matter), NOx, carbon monoxide (CO) and hydrocarbons (HC) in power generation industries.

Yes, we can supply solutions to suit various generator node sizes comprising engine powers from 60kW to 3MW for every different power requirement in a variety of power generation sectors.

This allows a wide variety of generator operators to install exhaust emission aftertreatment systems to reduce power generation emissions.

Yes, there are no specific age requirements on upgrading a diesel generator already in service if it has been maintained to a good standard. We have a range of upgrade solutions for non-emissionised engines and those complying to previous standards.

These solutions suit a variety of engine power outputs and can be tailored to suit individual requirements.

The process for installing an emission aftertreatment system is generally less than 40-hours, however, this can be more if specific testing or commissioning is required.

We have a standard range of products available for a quick turnaround, or tailored designs can be agreed as part of your project requirements.

Each project is specified to ensure the correct exhaust aftertreatment system is developed to reduce power generation emissions and meet Medium Plant Combustion Directive (MCPD), Stage V emissions or local regulations.

The systems are specifically designed to meet the latest emissions standards with a low operating cost. Adblue is generally consumed at a rate of 3-5% of diesel. The systems are a servable item so will require periodic maintenance in line with your operating needs.

Eminox provides emission aftertreatment systems to reduce exhaust emissions from diesel- and gas-powered generators, ensuring compliance to Medium Plant Combustion Directive (MCPD), Stage V emissions or local regulations for all types and ages of power generators.

Our real-world proven systems reliably reduce Particulate Matter (PM) and Nitrogen Oxide (NOx), supporting the power generation industry’s drive to reduce global air pollution.

The Eminox systems are developed using a standard range of components, providing a modular and scalable platform product range. So, you can choose a standard product as well as bespoke solutions tailored to your requirements.

Eminox can provide all service requirements and replacement parts based on the operating hours of each application, with all serviceable components available to maintain the system.

Depending upon the generator set duty cycle service intervals can vary however, at the point of project enquiry, all service plans will be recommended by Eminox.

Yes, they can. Our systems are MCPD, EPA Tier 4 regulations and Stage V compliant covering hire, emergency backup, prime and continuous rated generators meaning solutions for both temporary and permanent installations are available.

Our emission aftertreatment systems for the power generation industry are suitable for 60kW to 3000kW engine power outputs.

Our SCR technology ensures NOx compliance for diesel gensets. Adding a DOC/DPF reduces up to 99% of harmful PM, achieving Stage V standards. This showcases generator owners’, operators’, and manufacturers’ commitment to Environment, Social, and Governance (ESG) principles.

We offer emission aftertreatment systems in various sizes to fit different engine power outputs. A recent project featured a compact system for a 1,400kVA generator, mounted on the roof to save floor space. The system measured 2550mm (l) x 1830mm (w) x 1740mm (h). Our flexible, scalable, modular design allows us to tailor solutions for any genset type and space constraint, ensuring compliance with emissions regulations. Each system is sized to match engine exhaust flow, back pressure, and NOx conversion needs. This approach helps achieve near-zero emissions of PM, NOx, CO, and HC across power generation sectors, including data centres.

Yes, we can supply solutions to suit various generator node sizes comprising engine powers from 60kW to 3MW for every different power requirement in a variety of power generation sectors.

This allows a wide variety of generator operators to install exhaust emission aftertreatment systems to reduce diesel and gas exhaust emissions.

Yes, there are no specific age requirements on upgrading a diesel generator already in service if it has been maintained to a good standard. We have a range of upgrade solutions for non-emissionised engines and those complying to previous standards.

These solutions suit a variety of engine power outputs and can be tailored to suit individual requirements.

The process for installing an emission aftertreatment system is generally less than 40-hours, however, this can be more if specific testing or commissioning is required.

We have a standard range of products available for a quick turnaround, or tailored designs can be agreed as part of your project requirements.

Each project is specified to ensure the correct exhaust aftertreatment system is developed to reduce power generation emissions and meet Medium Plant Combustion Directive (MCPD), Stage V emissions or local regulations.

The systems are specifically designed to meet the latest emissions standards with a low operating cost. Adblue is generally consumed at a rate of 3-5% of diesel. The systems are a servable item so will require periodic maintenance in line with your operating needs.