We can help you reduce emissions

Eminox Group of Companies delivers global solutions, from our local European, Indian, North American and UK facilities

Connect with usOur Heritage began in 1978 when Eminox was founded by David Milles and Norman Emerson. We have grown from a team of three based in the UK to more than a 200 strong workforce based across Europe, India, North America and the UK and have developed our product ranges from exhausts to market-leading new technologies in markets around the world.

We redesigned and manufactured our first exhaust system in 1978, resulting in our first large order of 30 units. Word quickly spread of the high-quality stainless-steel manufacturing Eminox offered.

We invested in state-of-the-art technology, introducing laser cutting machines in 1984, and took a leap of faith buying an Apricot microcomputer, with no comprehension of how crucial they would become. Orders continued to flow and Eminox expanded into a 6.5-acre site of new offices and manufacturing space in Gainsborough, UK.

Markets were continually changing, and it became apparent that although the truck and bus markets were still expanding, there were opportunities in off-road industries, such as rail, agricultural and non-road mobile machinery (NRMM).

Eminox began developing systems for heavy cranes, initially for operators, which consequently lead to supplying for Original Equipment Manufacturers (OEM). This expanded to include other applications such as pea-viners and standby generators for operations in demanding conditions like the South Pole and Hollywood.

We received our first £1m order in 1990 when we expanded into the rail industry with exhaust systems for diesel multiple units. Eminox entered the European market with products being distributed in Sweden, shortly followed by further expansion in other countries in 1992. A proud moment in Eminox’s history.

Back in the UK, the business continued to invest in state-of-the-art equipment to keep up with demands. With our customers in mind, we built our own Test Cell where all products go through rigorous testing. This ensures they meet and exceed all project requirements before undergoing official approval.

As a result, our customers save development time and costs as any required alterations are resolved before official testing takes place.

In the early ‘90s, environmental pressure was building to clean up diesel exhausts. In 1994 Eminox partnered with Johnson Matthey (JM), which introduced patented chemical technology. Together with Eminox’s modular case design, this resulted in the creation of the Continuously Regenerating Trap (CRT®), which has been fitted in more applications around the world than any other system of its kind.

Eminox launched the SCRT® system in 2001 in collaboration with JM, a product installed worldwide with OEMs as well as retrofitted to a variety of on-road and off-road applications. Orders continued to grow, resulting in further expansion of our manufacturing and office space. We moved into a new 7,500m2 facility in Gainsborough in 2013.

As the second decade of the 21st century commenced we invested in new technologies to support evolving emissions legislations and the products and manufacturing capabilities to support them.

Our EMx Controls was developed and launched in 2020 in response to the growing market need for turnkey exhaust aftertreatment systems for specialist and low volume applications. The ECU is configurable, per application, for maximum performance and emission reduction.

This innovation was closely followed by the launch of our Euro 6 DPF range, which enables owners and operators of Euro 6 vehicles remain compliant to E6 standards with cost-effective, OE-quality replacement parts. The range of type approved DPFs, for all major brands, can remove as much as 99% of Particulate Matter 2.5, proven to be damaging to public health.

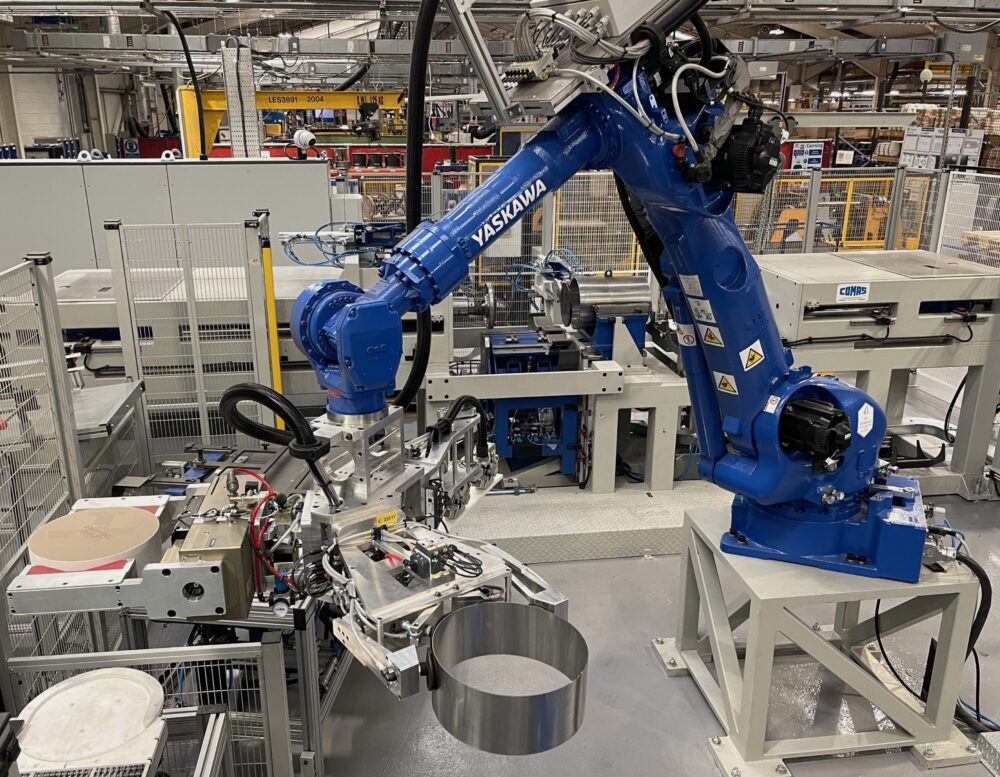

Investment in our sites is key to our manufacturing throughput and precision and in 2024 saw an investment of more than £1m in equipment to bring tangible benefits to all our stakeholders.

This included the installation of a Comas automated canning line in 2024, which provides flexibility and consistent quality in volumes to suit customer demand for our exhaust aftertreatment systems. This is complemented by a Comas servo press with a capacity of 80 tonne, with a large bed area to accommodate larger tools giving greater flexibility for customers. Additionally, a large scale welding platform brought an enhanced level of accuracy to our production capabilities.

Continued expansion was key to securing our future in diverse markets and futureproofing our global capabilities allowing us to continue supporting global emissions control and compliance.

In 2021 Eminox formed a joint venture in India with the market-leading business IP Rings (IPR), part of Amalgamations Group, India.

Based in Chennai, the exciting collaboration was established to explore ways to cost effectively meet the Indian BS/TREM V off-highway and BS VI Stage 2 on-highway emissions standards which came into force in 2024.

Key to our ongoing expansion was the opening of our Central European, 5,700m2 production facility in Svit, Slovakia; a pivotal moment for Eminox. This allows greater support for our European customers by manufacturing OEM exhaust aftertreatment systems, remanufacturing of the exhaust aftertreatment systems and ancillary parts, and offering DPF cleaning of HD & LCV diesel particulate filters.

We completed the acquisition of SaveGuard in 2024 expanding into the thermal and acoustic insulation global market.

Offering complementary products to those manufactured by Eminox, SaveGuard engineers high-performance insulation products used in vehicle engine bays, exhaust systems and more, including KatPak substrate support mat, bespoke sleeves, insulation jackets, and heat shields.

The Firehalt brand was established by SaveGuard in the 1980’s and formed part of our dual acquisition strategy in 2025.

Firehalt is a leading manufacturer and widely recognised name in passive fire protection systems, offering a comprehensive range of barriers, penetration seals and access hatches engineered to meet all required industry standards.

Firehalt products are compliant with building regulations across the UK:

England & Wales – Approved Document B, Northern Ireland – Part E, Scotland – Part 2 and Republic of Ireland – Part B. Its products will become compliant also to EU standards (EN 13501) from September 2029 as BS 476 is phased out.

2025 saw a strategic organisational development of the business to support the next phase of growth across our brand portfolio.

We re-defined the organisation to create a clearer, stronger and more connected group structure. We formed the Eminox Group of Companies as our overall parent company for SaveGuard, Ceramex, Firehalt and Emission Control by Eminox – the new name for the business previously known as Eminox.

This development strengthens our ability to add value for our customers, enhance our operational performance, and position our business for continued long-term success.

As a leader of technologies for a greener planet Eminox exhaust aftertreatment systems achieve the latest global on- and off-road emissions standards, reducing NOx, NO2 and PM by up to 99%. We help achieve legislative emissions targets by providing exhaust aftertreatment solutions to upgrade heavy-duty vehicles and equipment and meet global emissions standards.

Our Heritage began in 1978 when Eminox was founded by David Miles and Norman Emerson.

Exhaust design and manufacturing excellence began.

A ground-breaking Eminox product innovation

Parent company of Eminox.

Eminox collaborative product innovation

Thermal & acoustic product development

Eminox Group of Companies delivers global solutions, from our local European, Indian, North American and UK facilities

Connect with usCopyright 2026 Eminox Registered in the UK Registration NO. 01349209 CRT and SCRT are registered trademarks of Johnson Matthey plc.