DPF and SCR emissions reduction technologies

Eminox exhaust aftertreatment systems (EATS) for PM and NOx reduction are designed with a diesel particulate filter (DPF), urea dosing system (UDS) and selective catalytic reduction (SCR) catalyst. They can reduce particulate matter (PM), nitrogen oxides (NOx, NO2), carbon monoxide (CO) and hydrocarbons (HC) by up to 99%, even at low operating temperatures.

All Eminox EATS are developed to minimise the overall package space required and our advanced urea mixing techniques ensure high performance whilst minimising the overall SCR catalyst volume. Our DPF units optimise the exhaust flow distribution under all operating conditions, therefore, minimising the regeneration frequency and reducing the total regeneration time for improved efficiency.

Our EATS are proven in real world operating environments and are compliant with Stage V and Euro VI legislation, as well as all equivalent current global standards. Sophisticated electronic control actively manages the system including the integration of the on-board diagnostics to ensure optimum system performance.

There is also the option to add the Eminox telemetry system to provide real-world, real-time data enabling you to manage, maintain and optimise your fleet therefore giving you the confidence in full compliance to the latest emissions requirements.

Our complete solutions provide a cost-effective route to compliance for all heavy-duty diesel powered vehicles and equipment which operate in the growing number of low emission zones being implemented globally. All of this delivers cost-effectiveness and high performance.

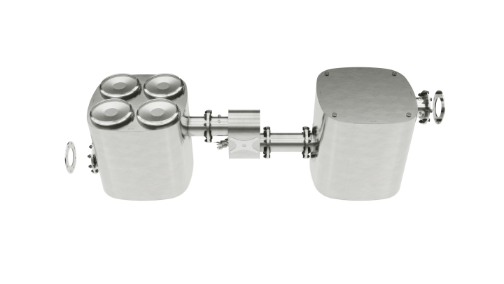

In-line EATS

In-line EATS suits on-road, construction, agriculture, rail, stationary power, and alternative-fuel applications. Designed for 37–350 kW, it’s telemetry-ready and fully serviceable, supplied as a fixed configuration without a repair and maintenance contract option.

|

|

Engine output | 37-350kW |

|

|

Telemetry |

|

|

|

Adaptable |

|

|

|

Fully Serviceable |

|

|

|

Repair and maintenance contract |

|

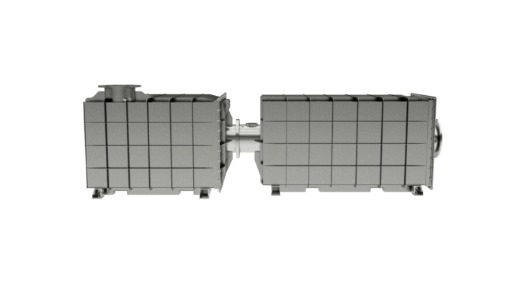

Close couple EATS

Close-couple EATS is built for on-road, construction, agriculture, rail, stationary power, and alternative-fuel applications. For 37–350 kW, it offers telemetry and full serviceability, delivered as a non-adaptable configuration with a repair and maintenance contract available.

|

|

Engine output | 37-350kW |

|

|

Telemetry |

|

|

|

Adaptable |

|

|

|

Fully Serviceable |

|

|

|

Repair and maintenance contact |

|

High speed platform

High speed platform EATS is engineered for power generation and marine applications. Covering 130–780 kW, it includes telemetry, is adaptable, fully serviceable, and can be supported with a repair and maintenance contract.

|

|

Engine output | 130-780kW |

|

|

Telemetry |

|

|

|

Adaptable |

|

|

|

Fully Serviceable |

|

|

|

Repair and maintenance contact |

|

Medium speed platform

Medium speed platform EATS is designed for higher-output power generation and marine applications. Spanning 780 kW–10 MW, it delivers telemetry, adaptability, full serviceability, and optional repair and maintenance contract support.

|

|

Engine output | 780-10MW |

|

|

Telemetry |

|

|

|

Adaptable |

|

|

|

Fully Serviceable |

|

|

|

Repair and maintenance contact |

|