Gainsborough-based emission specialists Eminox Limited has been awarded a contract to jointly develop and manufacture Stage V standard exhaust after-treatment systems (EATS) with engine manufacturers Liebherr Machines Bulle SA.

The two companies will work together on Liebherr’s Low Power Engines (LPE) and High Power Engines (HPE), expected to launch in 2019.

Eminox has worked with Liebherr for many years, supplying silencers, pipework and specialist spark arrestors, and was also selected for Liebherr’s Stage IV EATS (the Liebherr SCR only system), which are currently in volume production.

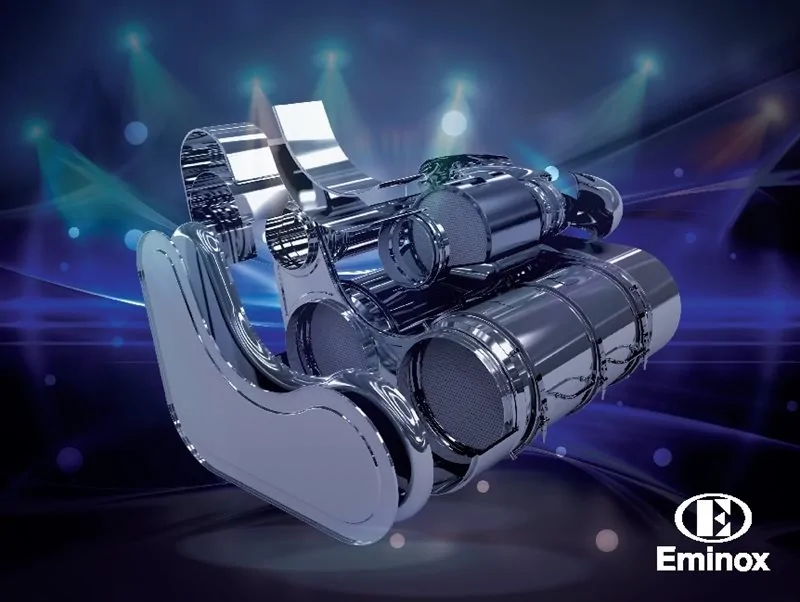

One of the most significant challenges of Stage V is the requirement for further reductions in particulate matter, including particulate number count (PN), demanding the use of DPF technology, alongside continued tight control of NOx. With Stage V legislation announced soon after the implementation of Stage IV, maintaining the space envelope for EATS was critical to Liebherr in order to avoid machine re-design.

The Stage V approach incorporates advanced exhaust after-treatment technologies including SCR on Filter technology, a DPF coated with SCR. Liebherr pioneered this technology under the brand name Liebherr SCRFilter, already at Stage IV, to produce a range of machines to meet strict local emissions requirements for countries such as Switzerland.

This was one of the key building blocks which Eminox used to develop a compact range of EATS variants for the Liebherr Stage V solution, packaged within an almost identical space envelope.